INSTRUCTIONS

Wastewater that is generated through industrial production processes are a constant source of harm to the environment. Consequently, in the industrial field, it is an important environmental challenge to find methods to recycle the wastewater or to reduce the cost of wastewater treatment.

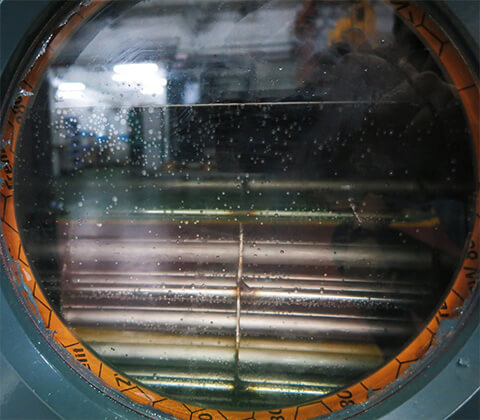

Through many years of technical skill developed from our heat pump compressors along with the application of vacuum distillation theories, Fusheng successfully developed a high-efficiency and low-energy "Vaccum Distillation Unit" to implement the standards of the ISO14001 and ISO50001 management system. Vacuum distillation is the process of separating solutions by heating and evaporating different components into vapor at different temperatures, and then condensing them back into separate liquids. With the excellent heating capacity of Fusheng’s heat pump, it can obtain three to five times more heat with one unit of power, allowing the equipment to perform the vacuum distillation process with less power consumption.

The HD series unit at the Fusheng Sanchong factory has been running for over a year now. Its energy-saving and wastewater-reduction outcome has been extremely obvious. On average, for every 20 barrels of wastewater that are treated, only one barrel of waste is extracted. The remaining 19 barrels of water can be recycled back for reuse in the manufacturing equipment. This effectively replaces the traditional combustion method, minimizing any concerns about air pollution.

Features

applications

Online

Chat

Online

Chat