INSTRUCTIONS

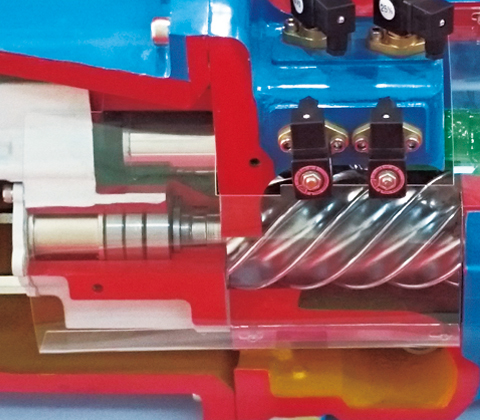

The CSRL series refrigerant compressors are designed based on Fusheng's newly developed helical teeth rotors and it is developed to meet the application requirements in the 7.5oC to -45oC medium-to-low temperature fields. Each compressor is tested under simulated working conditions of refrigerant systems and qualified with a CE certification. The CSRL series are 100% designed and manufactured in Taiwan.

Features

The highly efficient electric motor, from a well-known brand, is recognized

for its excellent stability and efficiency. It was built with a PTC

thermistor and the newest protection module to accurately monitor the coil

temperature of the motor and to ensure its normal functioning. The optimum

design of the cooling channel further expands the application scope.

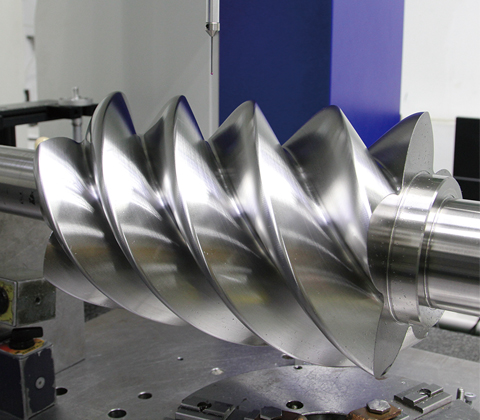

The Fusheng 5:6 asymmetrical rotor tooth is processed and formed by the

British HOLROYD rotor processing machinery and the German KAPP and

KLINGELNBERG precision rotor grinder. Rotors are strictly measured by the

German ZEISS and LEITZ three-coordinates measuring machine. They are

tremendously precise, efficient, stable and reliable. Optimal clearance

values between rotors are maintained, even under continuous operation,

allowing it to perform at the highest efficiency.

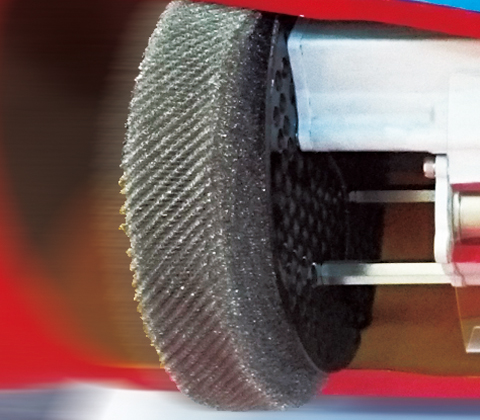

The capacity regulation valve can control the capacity modulation of the

system precisely. A selection of patented four-stage and step-less designs

are available for controlling the capacity regulation of the compressor.

Various built-in volume fractions can be chosen for application to

different coolant operating modes. An outboard solenoid valve is used for

control and in-load.

applications

Online

Chat

Online

Chat