INSTRUCTIONS

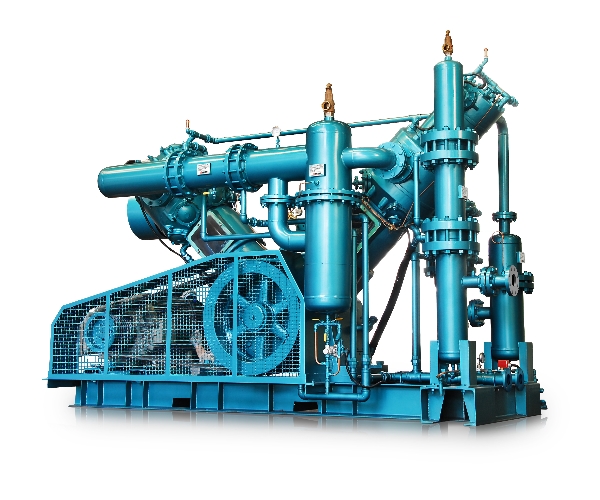

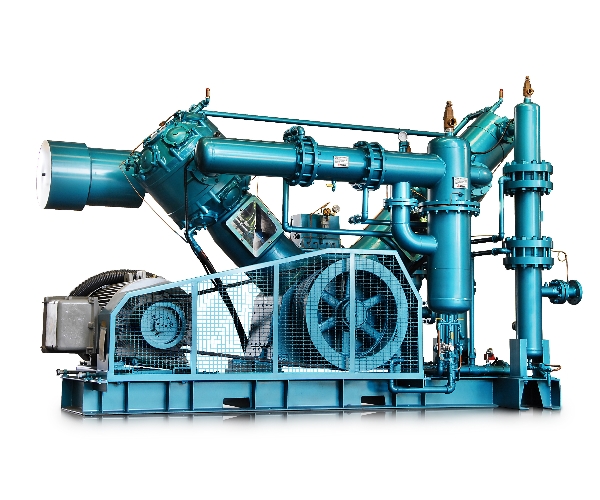

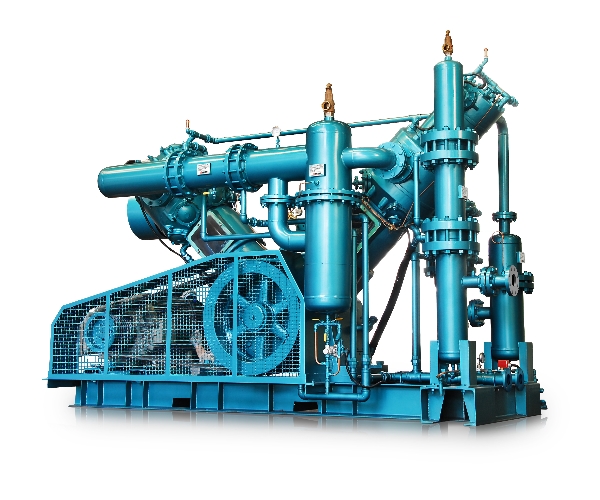

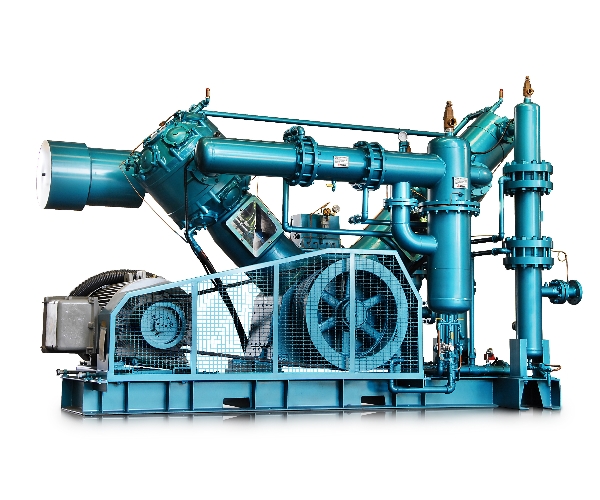

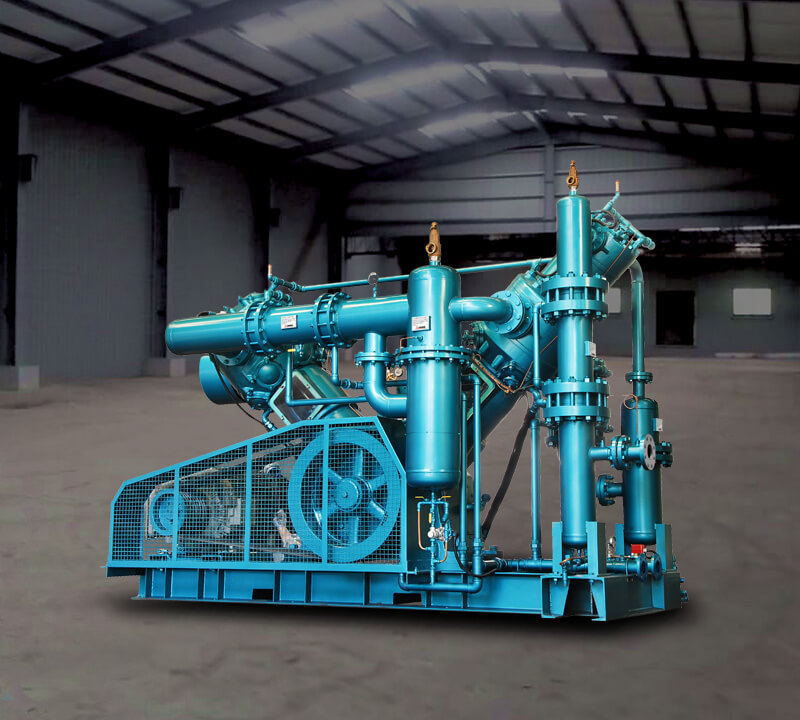

The Fusheng VFW oil-free, high-pressure, 100% clean air compressor series is specially designed for the PET blow molding industry. Drawing from the wealth of experience gained from long-term operations in varying conditions, the compressors are engineered to be highly efficient and reliable as they provide a stable supply of compressed air for blow molding. The series ranges from 50 to 300HP with discharge pressures ranging from 25 to 40 kg/cm2 and is accommodated for variable injection volumes. The VFW series has a built-in user-friendly interface, touch-screen panel, and PLC control system. The compressor is equipped with multiple alert systems and safety features for better overall control. Operating parameters, status, and servicing instructions are shown on the monitor to provide the user with important data concerning periodic and preventive maintenance.

Features

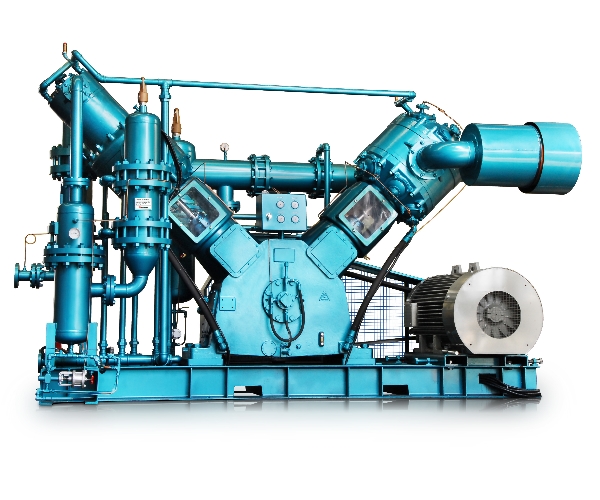

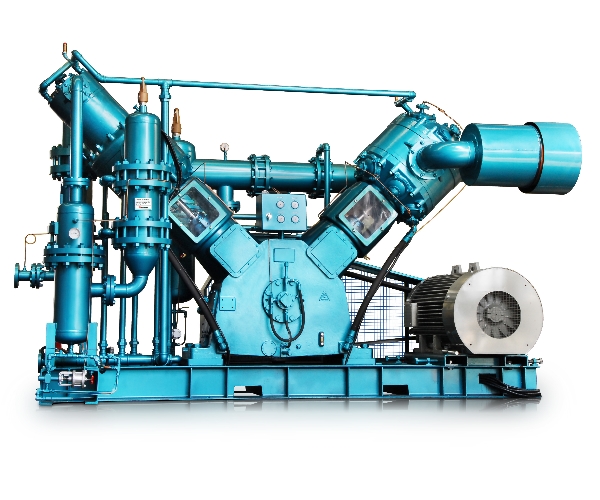

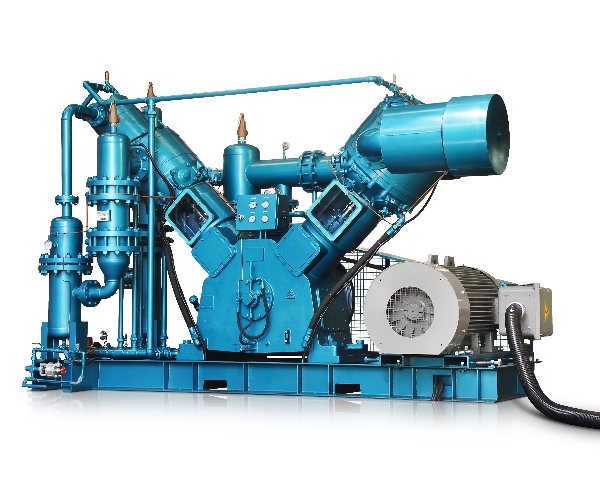

Each standard model features capacity control ranging from 0% to 100%, but

customization for 0% to 50% to 100% is also available. Automatic flow

control can automatically perform loading/unloading adjustments to avoid

machine halts from over-idling, and to prevent the compressor from

frequently turning on/off and idling. As a result, energy saving can be

achieved, the service life of parts are prolonged, and maintenance costs

can be reduced.

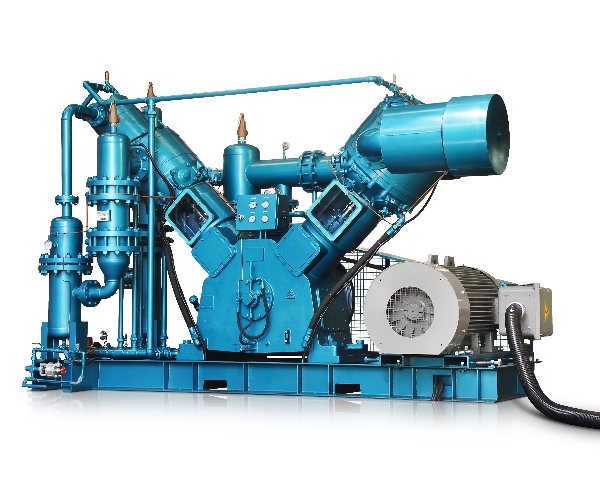

The PLC control system offers a user-friendly interface. It is equipped

with multiple alert systems and safety features for better overall control.

Real-time operating parameters, status, and servicing instructions are

shown on the monitor to provide the user with important data concerning

periodic and preventive maintenance.

applications

Online

Chat

Online

Chat